Non Destructive Controls (CNDs) are the set of examinations, tests and surveys that seek and identify any structural defects in a product, conducted using methods that do not alter the material and do not require the destruction or removal of samples from the structure in exam.

The acronym for Non Detective Testing is often used or the corresponding acronym PnD, derived from the Non Destructive Test.

In the industrial sector, every critical product (building beams, support screws, aeronautical components, automotive components, pressure vessels) must be checked to check its integrity and compliance with applicable standards. It is well-known that a small surface-clinker, which is harmless under normal conditions, undergoes fatigue stresses, constantly grows in size until the component breaks. The Non-Destructive Test Methods are used to analyze each single piece, replacing the most uncertain “destructive sample control” in many fields.

Among the methods of non-destructive controls, the following methods can be cited:

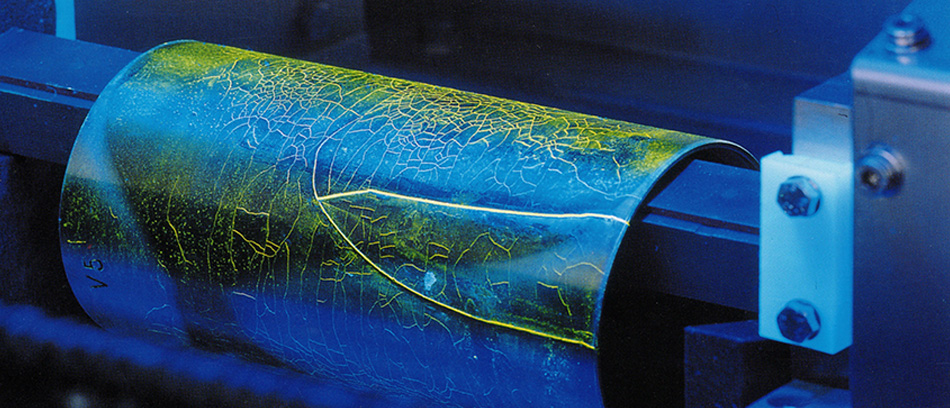

- PT – Penetrating Liquids, is based on the increased visibility of open surface defects by the use of liquid substance penetrating capillary defects (penetrating) and a background (detector or part itself)

- RT – Radiography, includes X-ray Systems, Neutron Method and Range Rays.

- UT – Ultrasound, a technique that uses high frequency acoustic waves (in the order of MHz for metallic materials, kHz for more heterogeneous materials such as stone and cement composites), and also includes the TOFD.

- ET – Induced current, technique based on the examination of parasitic currents induced by an alternating magnetic field

- VT – Visual test, visual control system

- MT – Magnetoscopy, based on attracting ferromagnetic particles and dispersed in liquid) attracted by the magnetic field dispersed close to any cracks

- AT – Acoustic emission, faulty propagation detection system

- TIR – Thermography, analysis of the thermal response in the presence of discontinuity of the material.

SMS Welding.it Studio, can carry out VT, MT, PT and TT (Civil, Electrical, Industrial, Welding) controls with qualified personnel and instrumentation.

For all other tests, including the destructive controls provided by International Standards, SMS Welding uses National and International Laboratories Recognition from Accredia® and the Ministry of Infrastructure.